R&D labs

Employees involved in R&D

Proprietary Technologies

Frankfurt, Germany

Innovative Zimmer® Polymer Technologies

Our Frankfurt R&D lab is the core innovation driver for Polymer Technologies fostering deep cooperation with partners and clients across polymerization and recycling processes. Uniquely equipped with bench and pilot scale facilities alongside state-of-the-art analytical tools, our experienced researchers and engineers deliver end-to-end R&D services, from concept generation and process development to small- and mid-scale sample production and full commercialization.

At every stage, we bring the technical expertise and rigorous methodology our clients need to turn ideas into validated, market-ready polymer solution.

- Semi-commercial, 1- & 2-stage batch pilot and Solid State Polycondensation (SSP) bench plants for polycondensation

- UV/VIS spectrometer, colorimeter, refractometer

- Viscosimeter, titrator, coulometer, polarograph y GC, HPLC, DSC

- R&D of proprietary processes, equipment and polymer recipe development

- Sample production/evaluation, process validation and commercialization

- Feedstock and polymer analytics according to international standards (ISO, DIN, EN, ASTM)

Weymouth, Mass., USA

Best-in-class Badger Process Technology solutions

The Weymouth R&D lab is built around one goal: helping clients and partners extend their research and development capabilities, faster and more cost-effectively. With a highly experienced team and a strong track record in process commercialization, we offer bench, pilot and demonstration scale services tailored to your project needs.

Our lab and engineering teams work side by side with clients to generate reliable data, accelerate decision-making, and bring novel process technologies to market with confidence.

Equipment

- Ten 24/7 fully automated pilot plants online gas chromatography (GC) and continuous process analyzers

- Fixed, fluid and stirred reactors and separation equipment

- Advanced analytical capabilities

- Gas chromatography - TCD/FID/MS/NPD/SCD

- Ion chromatography

- TGA

- LECO total carbon services

- Catalyst activity, selectivity and life testing

- Bench, pilot and demonstration scale testing and Technology evaluation

- Process scaleup and commercialization

Lyon, France

Processium® - Your process development partner

Our Lyon (Processium®) R&D lab is a wholly owned Technip Energies company dedicated to designing and developing the next generation of cost-effective, sustainable processes. From energy transition technologies to enhanced manufacturing competitiveness in sustainable chemicals, Processium® turns emerging challenges into viable industrial solutions.

With its newly established fermentation lab, Processium® is now expanding into renewable feedstock conversions, opening new pathways for the chemicals of tomorrow.

Conshohocken, Pennsylvania, USA

Developing advanced silicas products at every scale

At Conshohocken R&D lab, our highly experienced team supported by extensive laboratory and pilot-scale facilities for material synthesis and state-of-the-art analytical capabilities for characterization, drives innovation and accelerates new advanced silicas product development, including high-performance synthetic porous silica gels and functionalized silica materials. Through close collaboration with clients, we deliver comprehensive technical services and ensure rapid commercialization of advanced solutions.

- Silica gel processing

- Particle Sizing: Milling, Sieving, Air Classification

- Coating

- Thermal treatment

- Spray Drying

- Extrusion

- Emission control

- Packaging under inert atmosphere

- Aqueous and organic handling capabilities

- Porosity: N2 and Hg porosimetry

- Composition: AAS, ICP-OES, ICP-MS, XRF, GC-MS, HPLC, Ion chromatography

- Spectroscopy: Raman, UV-VIS, IR, near-IR, EDS

- Thermal Analysis: TGA, DSC, DTA

- Solution Characterization: Density, Viscosity, Turbidity.

- Particle Size/Shape/Color: Laser diffraction, Dynamic image analysis, SEM, Hunter Colorimeter

- Particle Strength: Flat-pate crush strength, Bulk crush strength, Sonic attrition

Zeolite powders and catalysts development, from concept to commercial scale

In zeolite supply, robust R&D is the cornerstone for progress. We establish true partnerships between client and supplier, collaborating to define requirements, create lab and pilot-scale prototypes, and develop manufacturing schemes. Our Zeolyst International commercial plants mirror the pilot assets, ensuring consistent quality and rapid scalability proven by our proven track record of successful zeolite commercialization.

- Zeolite Synthesis

- Ion Exchange

- Filtration and Washing

- Calcination

- Spray Drying

- Extrusion

- X-ray Diffraction

- Acidity

- Probe molecule adsorption (water, organics etc.)

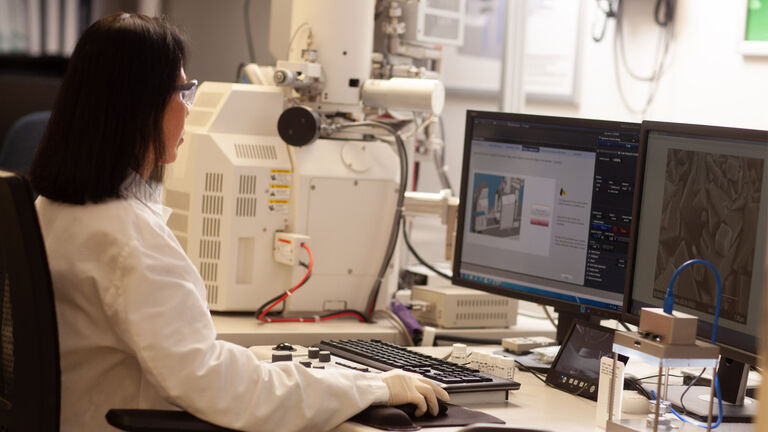

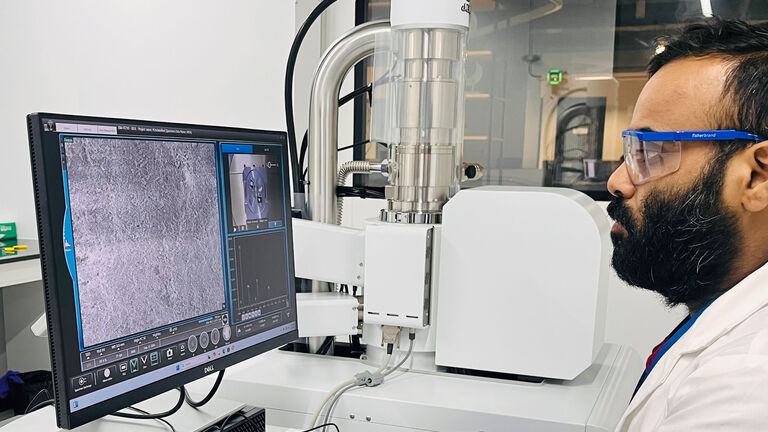

Chennai, India

Driving Innovation and new Technology Development

Technip Energies' latest R&D center has been established in Chennai, with a state-of-the-art facility designed to support of our mission to accelerate the energy transition. Equipped with advanced instrumentation and lab-scale process pilots, our center will play a key role in technology development, testing, and process optimization.

Strategically based in the IIT Madras Research Park, India's first university-based research park, it places us at the heart of a thriving ecosystem of world-class researchers, startups, and industry leaders, making it a true hub for collaboration and innovation.

Analytical Capabilities

- Porosity & Surface Area: N2 Porosimetry

- Particle Shape & Microstructure: SEM

- Crystallinity & Phase: XRD

- Molecular Fingerprinting: FTIR

- Optical Analysis: UV-VIS

- Elemental Analysis: EDX coupled with SEM

Phase Behavior & Combustion Study

- Simultaneous Thermal Analysis: TGA (mass change) and DSC (heat flow/phase transitions)

- Heat of Combustion: Bomb Calorimeter

- Gas Chromatography: GC-MS/FID/TCD

- Liquid Chromatography: HPLC & LC-MS

Additional information and downloads

Get in touch

Do you want to speak directly to our team?

Send a message using the contact us form (select Technologies from the dropdown menu below Projects & Solutions):