Technip Energies is a world leader in the ethylene industry with 40-50 percent of the licensing market share. With 65 years of experiences in the design, construction and modernization of the largest ethylene plants using proprietary technologies, our clients benefit from our unrivaled expertise.

We conduct conceptual studies for our clients that evaluate the technological robustness, CAPEX and environmental constraints of possible solutions leveraging our extensive FEED and EPC experience.

Our track record includes handling steam crackers from conception to commissioning with renowned references such as:

- DOW LHC9, the world’s largest steam cracker operating in the USA

- Sadara, the world’s largest mixed feed cracker in KSA

- Reliance, the world’s only dedicated refinery off-gas cracker in India

Major ethane crackers such as CPChem in the USA and Etileno XXI in Mexico.

Powering the energy transition with ethylene decarbonization for a cleaner climate

We have worked continuously to improve the energy efficiency of ethylene plants, lowering total installation costs per ton of ethylene and reducing hydrocarbon consumption per ton by 5-10 percent.

Our innovative low-emission ethylene cracker can reduce CO2 emissions by 30 percent. Other ways to decarbonize include adding post-combustion carbon capture to achieve up to 99 percent capture efficiencies and replacing the methane fuel from the process with alternative lower-carbon fuels such as hydrogen. We also are piloting a proprietary electric furnace and other advanced technologies.

Whether you need a new plant or an existing unit update, we can help you improve your energy efficiency and increase feed utilization and flexibility while lowering emissions.

of the ethylene licensing market share

new grassroots plants delivered since 2000

grassroots plants and numerous modernization projects

Comprehensive portfolio of proven ethylene technologies

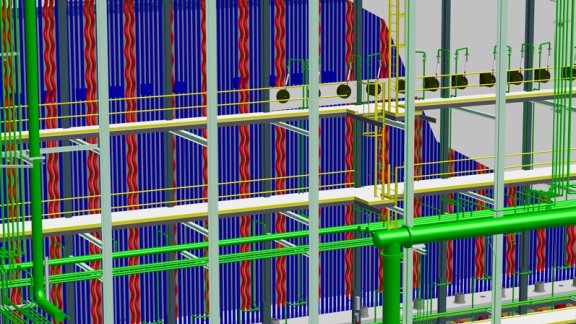

Our vast portfolio of proprietary technologies is designed to ensure our clients meet their production goals while reducing capital costs and improving operational efficiency.

- Furnace technologies: SMK™ and Ultra Selective Conversion (USC®) M-coils for gas cracking; GK6® and USC® U-coils for liquid cracking; Low CO2 emission cracking furnaces; and eFurnace™ by T.EN electric furnace

- Swirl Flow Tube (SFT®) technology to boost olefins production

- SPYRO® furnace design and optimization software tool

- Proprietary technologies for acetylene separation

- Hummingbird® ethanol-to-ethylene technology for producing sustainable products from bio-based materials

Our proprietary equipment

We also offer a variety of proprietary equipment, including transfer line exchangers (TLEs), burners, Ripple Tray™ technology, Vapor Flute™, Quench Fitting, Anti-Coking Heavy Feed Mixer™, WATT Winding Annulus Technip Energies Tube® and high-performance exchangers (Gewa-PB, Gewa-KS and DIESTA tubes).

Driving innovation for environmental and economic benefits

Full scope of services

- From licensing and conceptual studies to EPC

- Proven know-how in plant modernization

- Extensive expertise and experience

Economic and environmental benefits

- Reduction of steam generation through new design and increased electrification

- Reduction of hydrocarbon consumption per ton of ethylene produced by 5-10 percent

- Proprietary low-emission cracking furnace that lowers CO2 emissions by 30 percent

- eFurnace™ by T.EN can decrease furnace GHG emissions by more than 90% compared to a conventional furnace if the supply of electricity is from renewable sources

Additional information and downloads

Get in touch

Do you want to speak directly to our team?

Send a message using the contact us form (select Ethylene from the dropdown menu below Projects & Solutions):