Ammonia as a hydrogen carrier

Ammonia cracking is a chemical process in which ammonia (NH3) is thermally decomposed into its constituent gases, hydrogen and nitrogen, typically using a catalyst such as nickel at high temperatures (700–1000°C). This process is gaining attention as a method for producing hydrogen, particularly in the context of clean energy applications. Ammonia cracking to hydrogen is considered an efficient way to generate hydrogen on-site or during transportation, as ammonia serves as a convenient hydrogen carrier due to its high energy density and ease of storage.

With the growing demand for decarbonized energy, the global need for hydrogen also is rising. When transporting hydrogen over distances too long for pipelines, liquefaction is a solution, but it is a complex and expensive process. Using ammonia as a carrier enables the long-distance transport of hydrogen in a more cost-effective and energy-efficient manner while offering the advantage of easy storage.

Hynext by T.EN™: highly efficient, low-energy intensity ammonia cracking technology solution

Ammonia cracking holds significant potential for transforming the hydrogen economy. It will enable industries to transition to cleaner energy sources with minimal infrastructure changes, supporting hydrogen's role in renewable energy systems, and integrating intermittent sources like wind and solar.

Backed by 60 years of expertise in hydrogen and ammonia production plants, Technip Energies offers Hynext by T.EN™, a unique patented low-energy intensity ammonia (NH3) cracking technology solution.

Hynext by T.EN™ combines a high-activity, commercially proven cracking catalyst with advanced heat recovery technology to deliver exceptional efficiency.

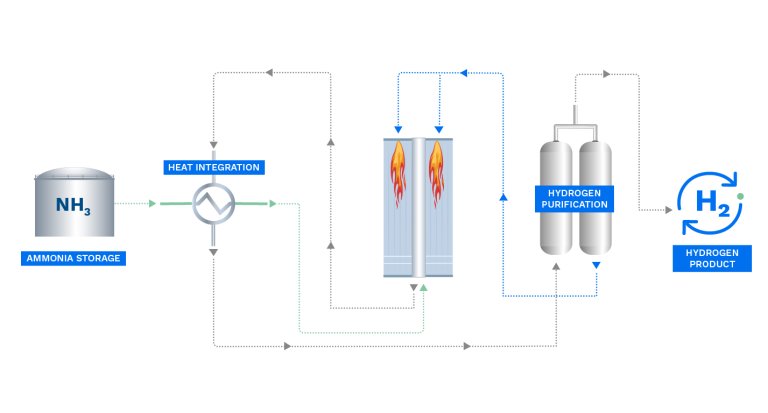

Our ammonia cracking process involves vaporizing and preheating liquid ammonia, then cracking it in a fired tubular reactor using a commercial catalyst. The recuperative concept recovers and reintegrates heat into the process, producing a hydrogen/nitrogen mixture. Hydrogen is purified to over 99.9 percent via pressure swing adsorption. Hynext by T.EN™ enhances efficiency by utilizing high-value heat, minimizing energy intensity, and reducing operating costs. Additionally, the carbon footprint can be eliminated by using carbon-free fuels such as ammonia or hydrogen, making it a sustainable and cost-effective solution for clients.

The Technip Energies LSV® Burners have been proven effective with various fuels, ranging from pure hydrogen to pure ammonia, as well as all relevant mixtures, enabling zero-carbon emission ammonia cracking.

Pilot plant in operation for advanced ammonia cracking

A pilot plant in Rotterdam has been launched to replicate industrial conditions on a smaller scale, providing a controlled environment for testing and refining process components.

The pilot plant's key objectives include:

- Confirming the suitability of metallurgies towards nitridation, which can lead to formation of metal nitrides and degrade reactor materials’ performance and lifespan.

- Evaluating the performance of different catalysts under realistic operating conditions.

The pilot plant enables fine-tuning of reaction parameters such as temperature, pressure, hydrogen purity, emission reduction and ammonia flow rate. By optimizing these conditions, Technip Energies has created a safe, reliable and economically efficient process.

Advantages of recuperative ammonia cracking

- Energy Efficiency: By utilizing waste heat, recuperative technology significantly lowers the energy consumption of the ammonia cracking process, leading to reduced operational costs and a smaller carbon footprint.

- Scalability: This technology can be adapted for various scales of operation, from small-scale applications to large industrial setups (>100,000 tons per year of produced hydrogen), making it versatile for different sectors including transportation, power generation and chemical manufacturing.

- Reduced Emissions: By eliminating the need for fossil fuels, recuperative ammonia cracking contributes to a reduction in greenhouse gas emissions.

- Hydrogen Purity: The technology can produce high-purity hydrogen, which is essential for applications such as fuel cells and industrial processes that require clean hydrogen.

- Economic Viability: With the integration of heat recovery systems, the operational costs are reduced, making hydrogen production from ammonia more competitive compared to other methods. Technip Energies ammonia cracking technology allows high hydrogen yield (typically above 80 percent) and a high overall plant efficiency (typically above 90 percent).

FAQ

Ammonia cracking is a chemical decomposition process in which ammonia (NH3) is broken down, or "cracked," into its constituent gases – hydrogen (H2) and nitrogen (N2). The chemical reaction for ammonia cracking is as follows:

2NH3 ⇌ N2 + 3H2

This reaction is endothermic, meaning it requires heat to proceed and takes place under high temperature and in the presence of a catalyst to improve efficiency and lower the energy requirement.

Ammonia (NH3) is considered an important hydrogen carrier because it addresses many of the challenges associated with long-distance transport and storage of hydrogen.

Hydrogen is a key component of the global transition to clean energy, but its practical use as a fuel or energy carrier is hindered by its physical and chemical properties.

At atmospheric pressure, hydrogen exists as a liquid at -253°C, which makes it very challenging to transport as liquid. Ammonia exists at -33°C at atmospheric pressure therefore offers a viable solution to these challenges, making it a critical enabler of the hydrogen economy.

Ammonia as hydrogen carrier helps improve the availability of clean energy in areas where the production of low carbon and/or carbon free hydrogen is less available due in the intermittency of wind and solar power or due to the of lack of space.

Ammonia cracking can be implemented in various scales and configurations to suit different needs. It can be centralized at large to mega-scale facilities, with hydrogen transported to end-users through extensive hydrogen grids, such as those being planned in Europe. Alternatively, it can be decentralized and large-scale, co-located with major hydrogen consumers and potentially connected via local hydrogen grids.

With 60 years of expertise in hydrogen and ammonia production plants, Technip Energies provides a uniquely patented, low-energy-intensity ammonia (NH3) cracking technology solution.

Based on the proven in-use recuperative cracking technology, Technip Energies offers a safe, highly efficient and effective technology that makes hydrogen available in a sustainable and affordable way.

Get in touch

Do you want to speak directly to our team?

You can browse our locations or send a message using the contact us form (select Ammonia Cracking from the dropdown menu below Projects & Solutions), both available on our Contact page.