Delivering innovation for harsh environments and operational constraints

Value-Driven Solutions for Sustainable Energy and Operational Excellence

Expertise is the hallmark of T.EN Marseille for monitoring, robotics and inspection systems. We work with an array of clients in the energy sectors, and manufacturing industries. This includes the nuclear sector, where our involvement dates back more than 40 years.

Our solutions help our clients increase uptime, reduce costs and improve safety and speed of decision-making through augmented NDT, monitoring and advanced robotics solutions for inspection and dexterous interventions.

Years of expertise

Projects executed

Experts working in France

Tailored solutions from standard building blocks

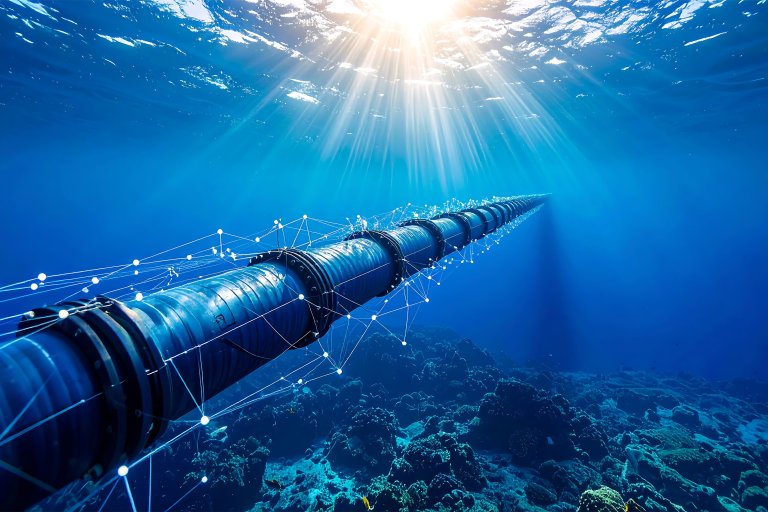

Offering reliable, non-intrusive solutions

for monitoring critical assets.

Leading monitoring technologies

Field-proven solutions enabling safe asset operation

T.EN Marseille specializes design, manufacturing and deployment of fit for purpose surveillance solutions ensuring a high level of reliability and accuracy (of the sensors, cabling and electronics), and offering installation versatility.

We supply systems to monitor the integrity and the performance of:

- Critical items of a production system (onshore transportation pipelines, hull, moorings, tendons, structures, risers and SPS)

- Causes of failure (corrosion, cracks, breakages, fatigue)

- Causes of degradation (temperature, pressure, sand).

Our systems combine monitoring and inspection solutions with our proprietary data management and processing software and can interact with our advanced robotics solutions.

Once in operation, we support clients throughout the life of the asset, providing services for site intervention, training, online monitoring, remote trouble shooting and spare parts management.

Delivering a tailored roadmap for robotics automated solutions

to maximize uptime, enhance safety and reduce operational costs.

Advanced robotics solutions

We support clients throughout the entire asset lifecycle, assessing the benefits of implementing robotics automated operations solutions from the earliest stages.

Asset operators are seeking ways to secure the uptime of their assets, while drastically reducing costs, HSE risks and GHG emissions. Embedding robotics in their operations is a way to achieve these objectives.

Leveraging 40 years of experience in developing, integrating and deploying robotics solutions in harsh environment, we have matured an offering to execute remote and autonomous Inspection, Maintenance and Repair (IMR) operations in harsh environments such as subsea, high temperatures, contaminated or explosive atmospheres, nuclear sites, remote locations, relying on:

- Unique capabilities to assess robotics feasibility, accessibility and ROI (Return of Investment) through in-house methodology, a multi-disciplinary team of experts, a proprietary simulation tool and indoor and outdoor testing facilities.

- In-house capabilities to design, build, integrate, test and qualify robotics hardware and software, with a special focus and numerous references on dexterous manipulation with force feedback technology.

- A proprietary supervision software to remotely operate a heterogeneous fleet of autonomous robots.

- Access to a wide range of robots fit for client applications, being it for aerial, ground of subsea applications, and for any harsh conditions (ATEX, corrosive, contaminated).

Proposing best-in-class

final finish equipment.

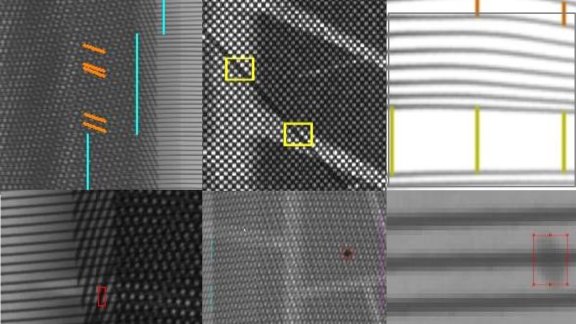

Pioneering excellence in X-Ray solutions

Achieving Industrial Excellence with Visionary Inspection Technologies

We are a leading provider of Hardware & Software quality control solutions, allowing leading companies fast and reliable decision making on their critical products. From the design of automated equipment to the development of specific softwares for the Energy, Defense, Aerospace, Pharmaceutical and Tire industries.

We are recognised as an innovative company for our engineering expertise and for maintaining strategic assets in the long term. We offer a comprehensive range of know-how that includes Automation, Control/Command, Image Processing, Artificial Intelligence, X-ray systems, Computed Tomography, Commissioning and Maintenance services with obsolescence management globally.

Additional information and downloads

Offshore Monitoring Flysheet

CyXense® Commander Flysheet

CyXpert AI Flysheet

OTRX series Flysheet

Get in touch

Send a message using the contact us form:

Select Monitoring, Robotics and Inspection from the Commercial contact per solution dropdown, or send a message using the contact us button below.