We are LNG pioneers advancing the energy transition

The international community is facing a triple challenge to secure energy supplies, reduce its carbon footprint and maintain energy sales prices. Natural gas is essential to the energy transition since it enables the production of electricity with a significant reduction of CO2 emissions.

In this market, liquefied natural gas (LNG) is the sector with the largest growth forecast, increasing about 50 percent by 2030 and more than 100 percent by 2040 due to its energy supply flexibility, security and ability to be easily transported over long distances.

Drawing on 60 years of experience, Technip Energies is committed to enhancing our clients’ project performance and accelerating the energy transition by offering solutions to reduce CO2 emissions from gas liquefaction and export terminals.

We have combined our engineering, technological and project execution expertise to develop SnapLNG by T.EN™, a new approach to decarbonize our clients’ LNG production and reach their carbon reduction targets through pre-engineered and standardized modules.

The Solution Zero for low-carbon LNG

A unique modular and standardized approach

SnapLNG by T.EN™ consists of 2,5 Mtpa train modules delivered to our clients’ door, ready to be installed, self-functional and pre-commissioned with no or minimal adjustment.

Our Solution Zero for low-carbon LNG benefits clients with faster time to market and faster revenues, saving more than two years in overall project development duration under a de-risked execution scheme.

Committed to a sustainable future, we designed SnapLNG by T.EN™ with electric motors to drive the refrigerant compressors, offering decarbonized production and avoiding ~350 kTe/year per train of CO2 emissions versus a gas turbine-driven solution.

With pre-engineered and standardized LNG modules instead of tailored projects, our clients can save more than two years on total project duration.

SnapLNG by T.EN™’s design provides greater LNG train reliability, rising plant availability to approximately 97%, which means increased yearly revenues. Our unique approach provides certainty in cost execution, delivery schedule, plant reliability and availability and plant performance.

Mtpa per Train

saving 2 years in project duration

CO2 emission in operation

plant availability

LNG reliability and performance at every scale of the value chain

SnapLNG by T.EN™ delivers a complete LNG liquefaction plant with simplified project execution. Our solution offers certainty in costs execution, delivery schedule, plant reliability and availability and plant performance.

- Our design delivers greater LNG train reliability, increasing availability from 93% to about 97% and representing +15 days of production per year.

- With our accessible fabrication yards, our clients benefit from a commitment to on-time delivery at a cost fixed at the time of FID. Plus bulk quantities are reduced, directly impacting scheduling and costs.

- Using its modular approach, SnapLNG by T.EN™ minimizes onsite labor for greater efficiency and meets all project needs.

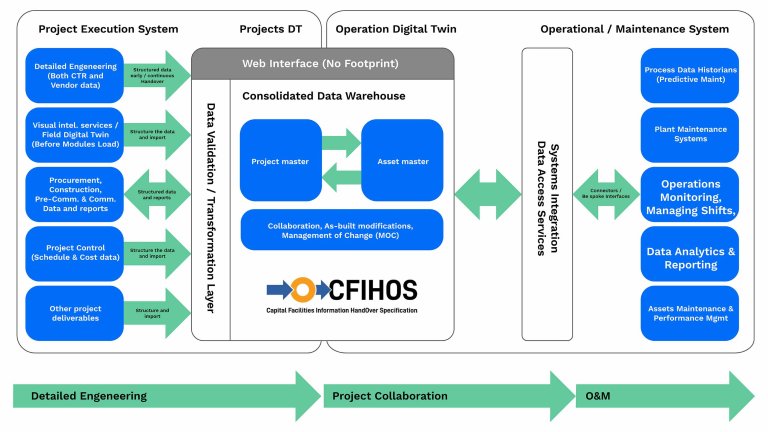

Optimized asset lifecycle performance

The strong data model and foundation developed during the standard FEED of SnapLNG by T.EN™ provides a solid backbone for FEED completion and EPC phases and beyond for operation and maintenance.

Optimize your decarbonization strategy

Optimize your decarbonization strategy with SnapLNG by T.EN™, featuring state-of-the-art modular LNG designs and cutting-edge digital solutions.

This technology offers low or no-carbon emissions LNG production through electrification and efficient technologies and equipment, enabling our clients to meet environmental targets while ensuring reliable LNG production strengthened by de-risked economics and shortened timelines.

Taking advantage of the LNG market

Take the lead today in the liquefied natural gas market by teaming up with a unique partner with the expertise to support clients from project desin to delivery, operation and maintenance.

Meet your LNG emission reduction targets by making the transition to environmentally friendly solutions. Execute your LNG projects more efficiently with rapid implementation, confidence in quality and certainty of success.

With SnapLNG by T.EN™, you can implement low-carbon LNG projects quickly, safely and effectively.

Additional information and downloads

PODS brochure

FAQ

Low-carbon LNG is liquefied natural gas produced with almost no carbon emissions, either native or anthropogenic. SnapLNG by T.EN™, a modular design, uses electrification and advanced technology to lower the carbon intensity of LNG production, contributing to a more sustainable energy supply.

Low-carbon LNG offers a cleaner alternative to coal, oil or other fossil fuels with reduced greenhouse gas emissions thanks to its high H/C ratio, aiding in the global transition to a more environmentally friendly energy market and helping meet climate goals.

SnapLNG by T.EN™ reduces CO2 emissions through electrification of high-efficiency processes and integration of carbon capture technologies, making LNG production more efficient and environmentally friendly.

Standardized modular LNG plant design provides certainty in terms of cost and accelerated project timeline by minimizing on-site labor activities. This approach also allows for easier scalability, phasing and adaptation to market demand while maintaining high production standards.

SnapLNG by T.EN™ accelerates time to market thanks to standardized pre-engineering self-functional modules, allowing for parallel construction, and testing at fabrication yard. This streamlines the project execution process, reducing overall project timeline and allowing faster LNG to market from inception to production.

SnapLNG by T.EN™ is unique due to its combination of compact modular design, standardized components, low-CO2 emissions, highly efficient process, and advanced digital solutions, offering reliable, cost-effective, and low-carbon LNG production, tailored to meet global market demands.